Product

Technologic High-Flyer

Logistics

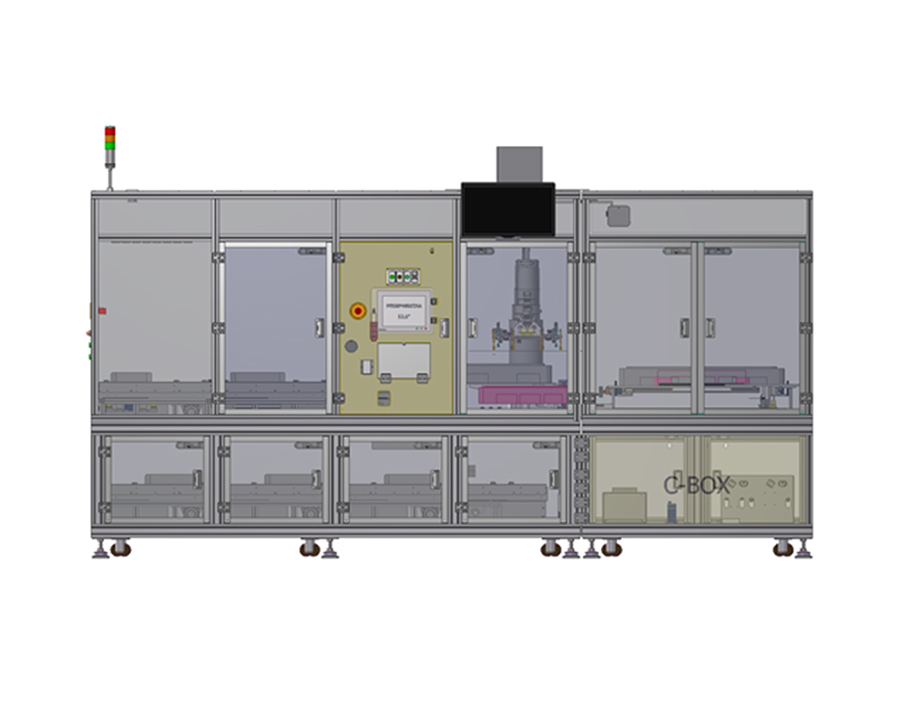

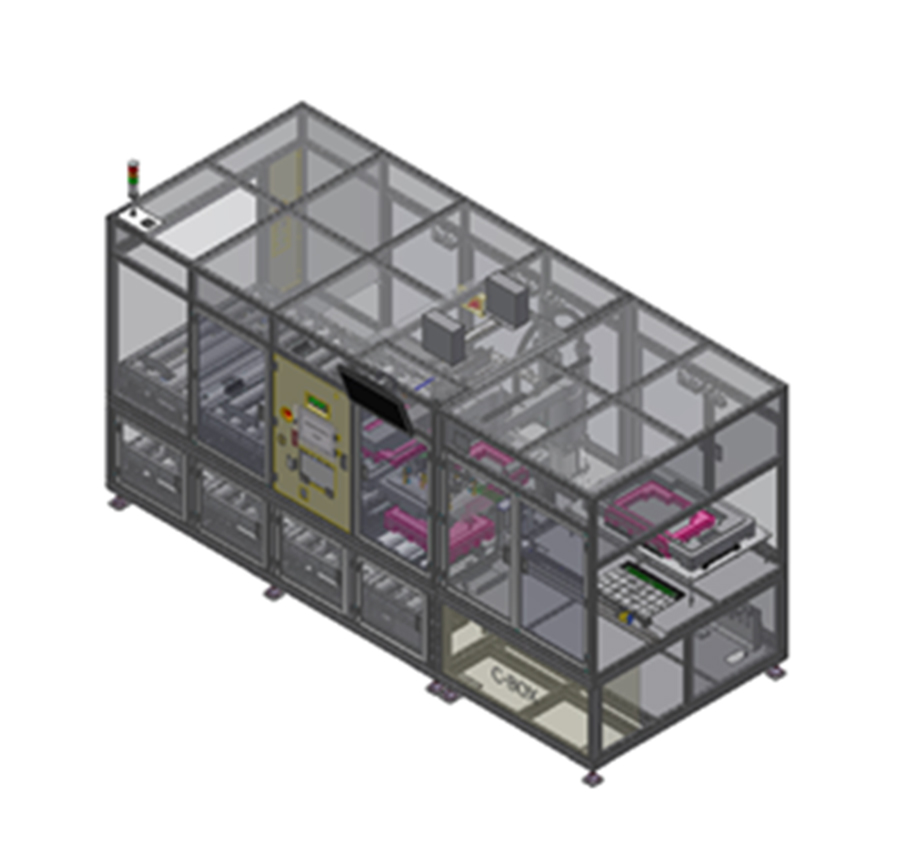

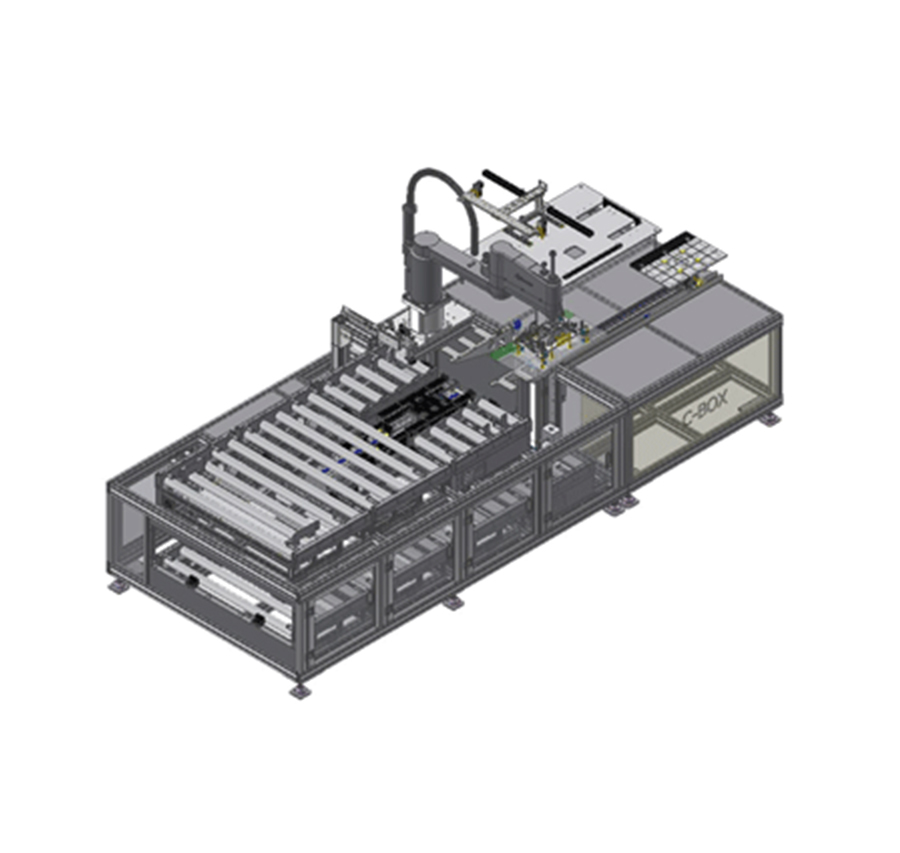

EPS BOX UNLOADER

Slip sheet movement by a SCARA robot.

It consists of an input conveyor, release conveyor, shuttle, vision alignment, centering unit and auxiliary slip sheet supplying unit.

Specification

| TACT TIME | 12.0 sec | ||

|---|---|---|---|

| Corresponding PANEL | 18.5" / 21.5" / 23.8" / 27" / 29" | ||

| Box moving logistics | manual | One side | |

| EPP BOX | 18.5" | 565 X 416 X 112 | Necessary to discuss the specification for loading slip sheets |

| 21.5" | 625 X 565.5 X 112 | Necessary to discuss the specification for loading slip sheets | |

| 23.8" | 625 X 565.5 X 112 | Necessary to discuss the specification for loading slip sheets | |

| 27" | 965 X 565 X 112 | Necessary to discuss the specification for loading slip sheets | |

| 29" | 965 X 565 X 112 | Necessary to discuss the specification for loading slip sheets | |

| AGV supplying stage number | 17" ~ 29" | 1 stage | 122mm |

| #. Slip sheet moving method: Handler | HANDLER / vacuum suction | using a SCARA robot | |

| Moving method for a work zone box | Conveyor / Lift | ||

| Unloading Pass Line | 400mm | ||

| Process Pass Line | 1000mm | ||

| Box Align | Vision | Recognition block alignment in a box | |

| Panel supply | SCARA ROBOT | Arm Length : 900mm (maker-robostar) | |

| Logistics in the equipment | Input to the upper part / Release from the lower part | Please refer to the separate layout | |

| Control method | PLC | Necessary to discuss the response to a PLC and a Robot Controller | |

| Environmental safety | CE Mark & KCS certification | Observation of Samsung’s Environmental Safety Standards | |