Product

Technologic High-Flyer

Logistics

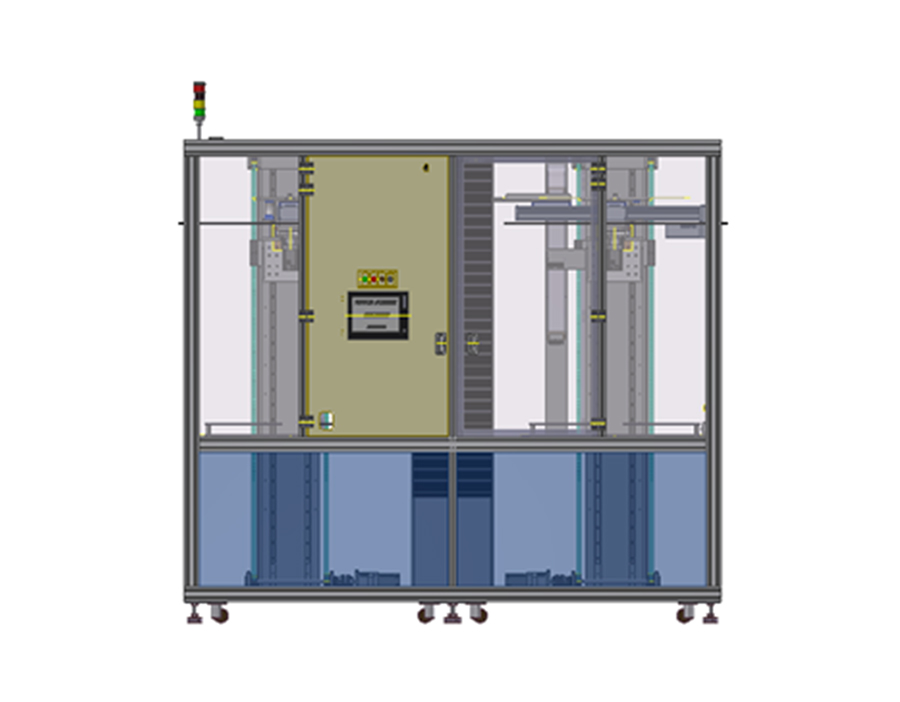

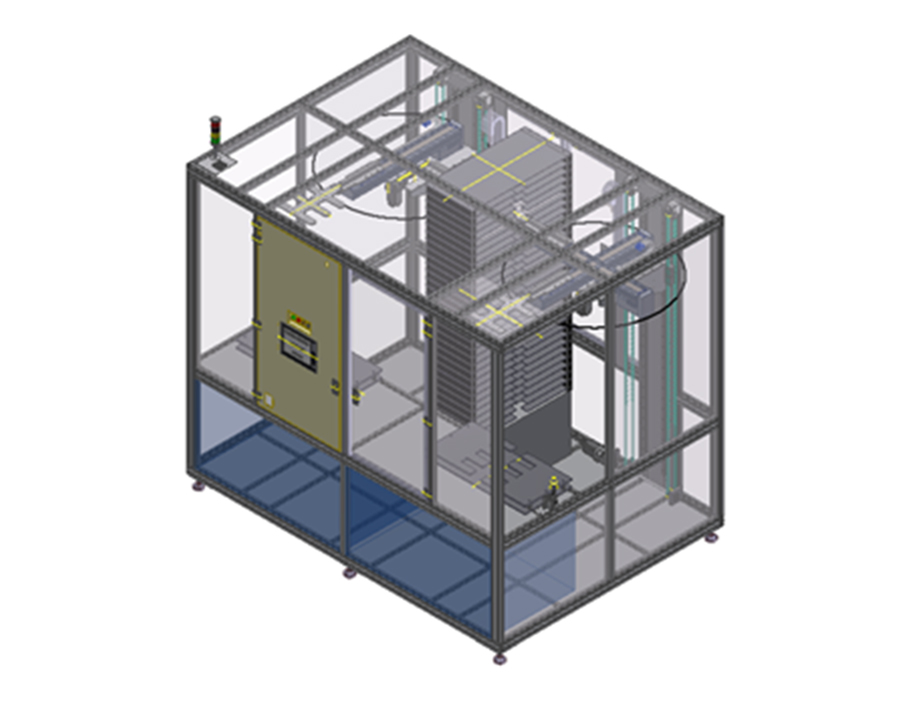

EPP BOX UNLOADER-1

Equipment putting a panel with PCB bonding completed into the Epp box using an articulated robot,

and covering a slice sheet taken out of an empty box on the panel for carry-out.

Specification

| TACT TIME | 12.0 sec | Excluding the tact time of a SCARA robot | |

|---|---|---|---|

| Corresponding Panel Size | 17" ~ 32" | ||

| Box moving logistics | Corresponding AGV | One side | |

| EPP BOX (Appearance tolerance1.2~2.5mm) | 17" | 570 X 420 X 132 | - |

| 32" | 955 X 560 X 65 | - | |

| Material (box) replacement time | within 12secs | ||

| AGV supply stages | 17" | 6 stages | Maximum height (box + slice sheet supply) |

| 32" | 10 stages | Maximum height (box + slice sheet supply) | |

| Slip sheet moving method | HANDLER / Vacuum suction | Movement : Motor, Vacuum Up/Down : Cylinder | |

| Moving method of work zone box | Handier / Gripper | Movement : Motor, Gripper : Cylinder | |

| AGV Pass Line | 400㎜ | In / Out detection sensor | |

| Total Process Pass Line | 1000 ~ 1050mm | ||

| Panel / Align | Vision | Stage seating accuracy ± 0.2㎜ / based on the edge of glass | |

| Logistics in equipment | Loading in the lower part/ Unloading from the upper part. | Please refer to the separate layout | |

| Control method | PC & PLC | ||

| Environmental safety | CE Mark & KCS certification | Observation of Samsung's Environmental Safety Standards | |