Product

Technologic High-Flyer

LAMINATOR

S-SHAPE LAMINATION

Equipment laminating Panel+OCAFlim, TSP+OCA, Window+TSP+Panel on the window glass with S-shaped curve

Specification

| Project | 7~17 inch S-Shape Laminator | |

|---|---|---|

| Production lead time | within 4 months after placing an order | |

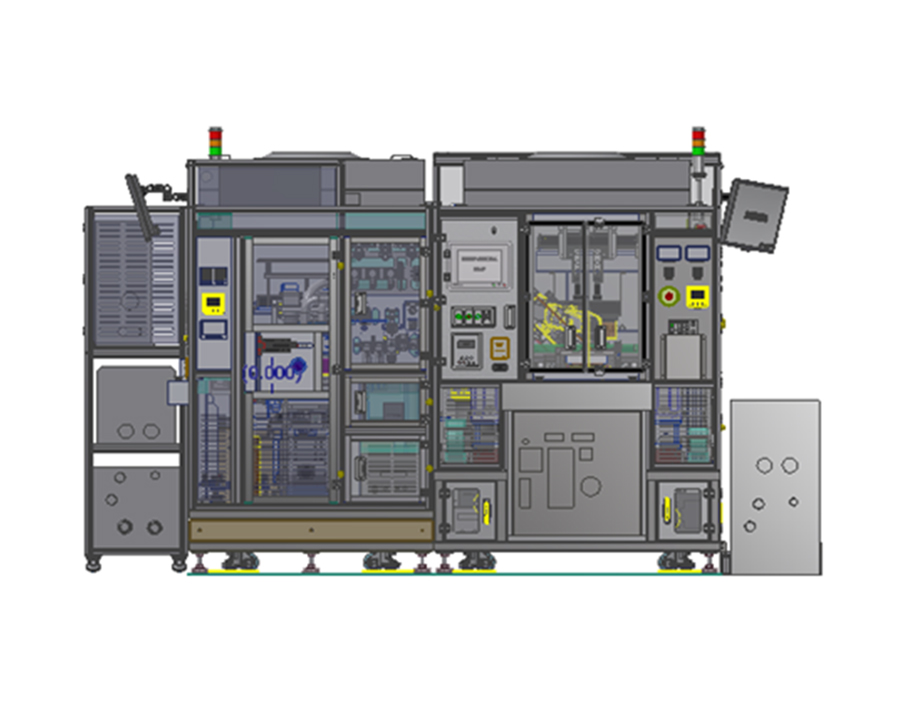

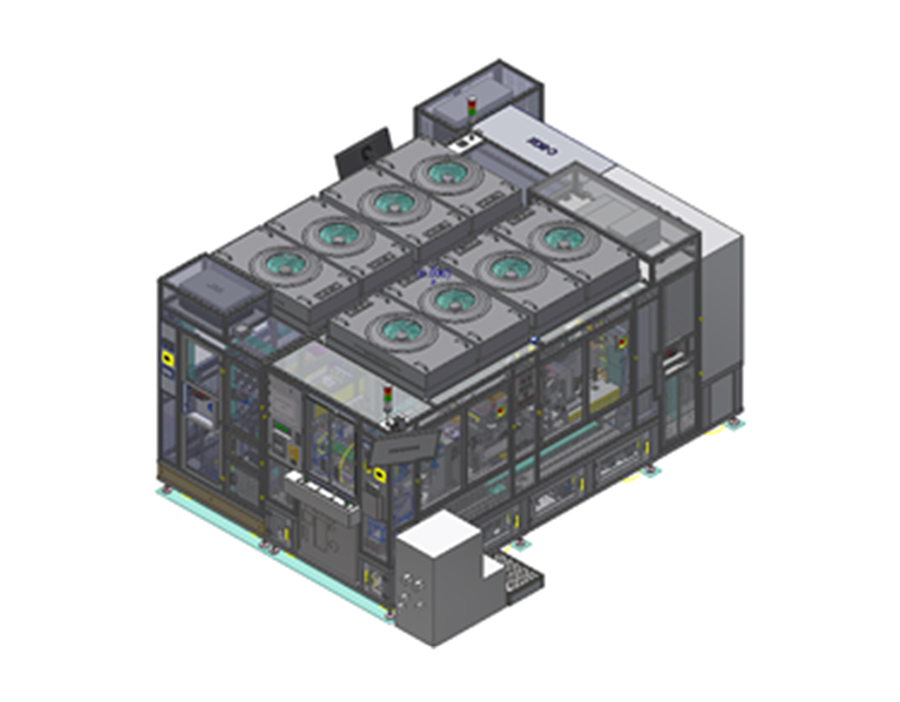

| Equipment Size | About 2,500(W) X 3,800(L) X 1,800(H) (except FU and 5mm gap of docking size) | |

| Applicable material size | min 7inch (94.2㎜ X 150.72㎜), Max 17inch (250㎜ X 385㎜) | |

| Applicable materials | Window, OCA, TSP, Panel | |

| Tact Time | TSP + OCA : 74 secs, Panel + OCA : 74 secs, Window + TSP + Panel : based on one cycle of 112 secs → USC cleaning 150㎜/s, plasma cross section cleaning 50 ㎜/s, foreign material inspection 100㎜/s, lamination 100 ㎜/s | |

| Applicable FPCB length | X, Y : 160 X 50 ㎜ | |

| Product input | Manual loading and unloading by an operator | |

| PF exfoliation | Operator’s manual exfoliation when supplying, robot’s automatic exfoliation before the main laminating work. | |

| Pass Line | Sub Lami : 975㎜ ± 50㎜, Main Lami : 1100㎜ ± 50㎜ | |

| Supply accuracy | Sub Lami : within ± 1㎜ (based on a marked line), Main Lami : within ± 0.3㎜ (in case that a guide is installed) | |

| Bonding accuracy | 7·8" | X-Axis : ± 125㎛, Y-Axis : ± 125㎛ |

| 8·17" | X-Axis : ± 300㎛, Y-Axis : ± 300㎛ | |

| Process capability index | ppk application, ppk 1.33↑ | |

| Response to 4 major qual | Observation of cleanliness, static electricity, environmental safety, and specifications of 8 systems | |